I’ve always wanted to make some real pioneer style wood ash lye soap! So I’m going to give it a try. I’ve done a bit of research using a ton of different books and websites so I can’t exactly reference any one specific recipe or site… so I’m making this up as I go along lol

First we started with collecting some ash from the fire pit. We like to smoke our meats and we use hard woods to do this (mostly ash wood or black walnut wood) so the ashes are from hard woods which my research says it should be hard woods to make lye water.

The plan

I don’t have a lye barrel to leach the ash, so I am using a stainless steal pot that I use to make my laundry soap (don’t use aluminum or it will eat the pot!) … to boil the ashes, then simmer for a while, then I will scoop the lye water off the top after letting the ashes settle to the bottom using a stainless steal metal measuring cup as my scoop and this will go into my glass canning jar for soap making. This jar will be labeled so it won’t get used for food in future because it has contained lye.

But first I need to render the tallow! So I called up the local butcher and placed an order for 8lbs of beef fat after telling him what I was attempting to do (I had no idea how much to order lol) which he sells for .75 cents a lb.

From what I have read on various sites and books I have come up with cutting the meat fat into small chunks, boiling it, then simmering so that the tallow rises up to the top of the water. Salt is required to help the process along and I’m going to add a teaspoon per Lb.

Salt is an important ingredient to solidify or harden soaps as I learned when making homemade Dish washer detergent previously. So I plan to add salt to the soap mixture once I get to that point in order to make a hard soap. The more salt the harder the soap is the theory.

So far my cost in making this soap (not including electricity used) is about $8. Not bad! Depending on how well it works and how well it turns out lol. But either way $8 for an experiment is still worth it! (Note: I only used half the beef fat I purchased so technically my first batch of soap cost less than $4 but read on for the exact details about that lol)

I also want to add some peppermint leaves from the garden! Peppermint is awesome for many reasons and I exclusively use peppermint soap. So out to the garden I go to gather some peppermint leaves which I will toss in the blender to get chopped as tiny as possible. I may in future make some homemade peppermint essential oils instead but for now I’m going to experiment with just the leaves 🙂

As you can see this is a multi day project since rendering the tallow will take a whole day by itself and left to cool in the fridge over night. So here are the photos as the project progressed and more detailed instructions of what I did and how it turned out.

The actual process

So basically I think I need about 2lbs of tallow to 10.5 oz of lye water. I put about half of the 8lb bag of beef fat (cut into small slices) that I got from the butcher into my handy dandy instant pot on manual high for 1 hour along with 4 teaspoons of salt and enough water to cover the beef fat.

You could do this by boiling and then simmering etc on the stove top but I’m a modern pioneer woman and I love my instant pot! Lol so instant pot it is! Besides… I’m thinking the pressure from the instant pot might just get more tallow from the cooking process without me having to resort to the old mashed potato masher method to squeeze out as much greasy oil as possible. So I’m all for that! Besides a pressure cooker (in a much more primitive form) has been in existence since 1679! So it’s possible it was done this way lol … that’s my story and I’m sticking to it!

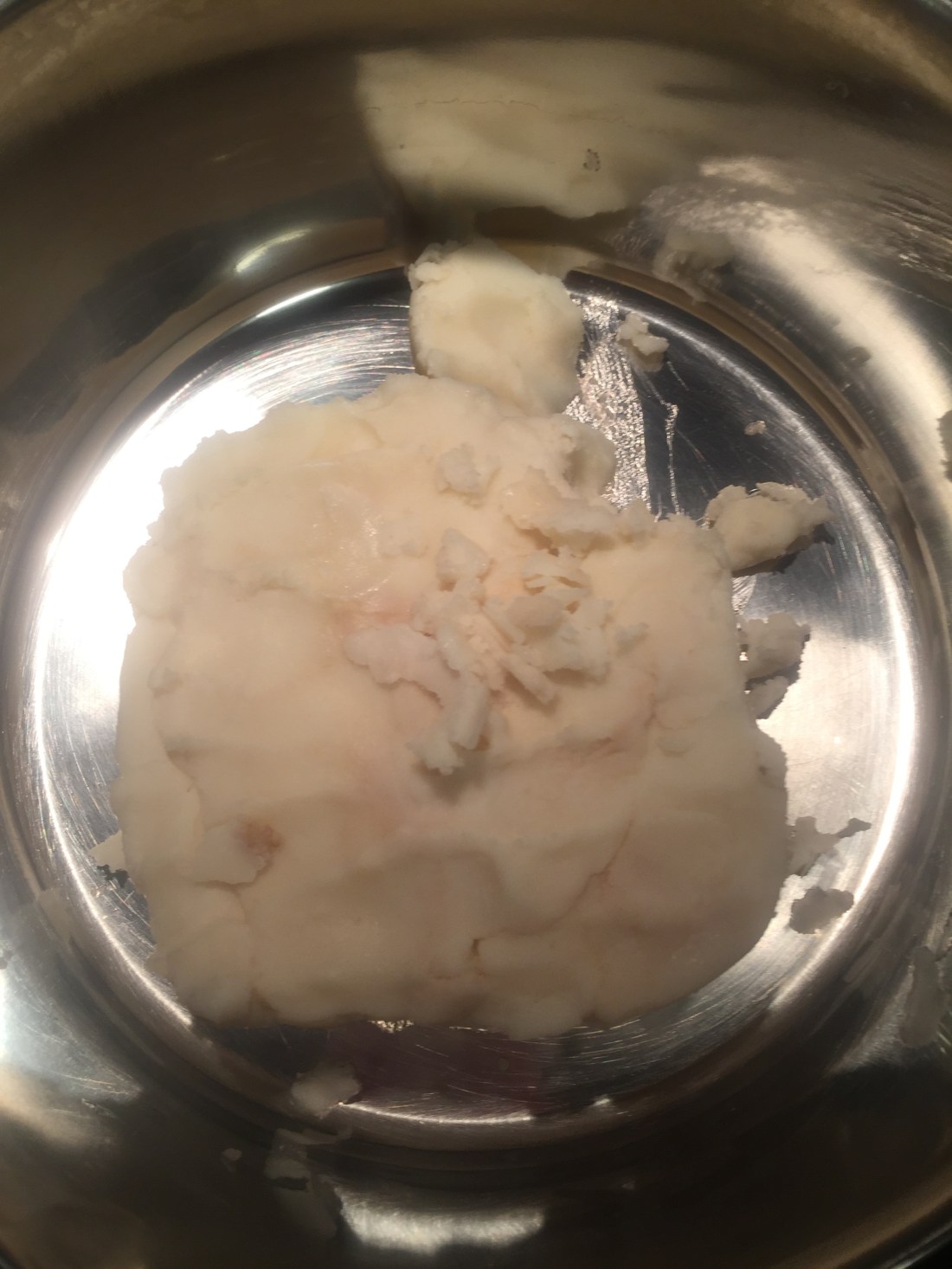

The next step is to pour the liquid thru a metal sieve to get the chunks of fat etc all strained out. You should see a nice thick layer of oil floating on top of the water. Once the oil layer cools it will become a white hard’ish substance which is the tallow we are after :). I’m going to let my tallow cool in the fridge over night and then start on the lye water tomorrow. Hopefully I have close to 2lbs of tallow from this batch! If not I will have to make another batch tomorrow.

Since I cut my beef fat into chunks (instead of using ground fat like some other recipes call for) I was able to just scoop it out of the liquid with the sieve and leave the juices to cool in the same pot I cooked it it. SCORE! I hate dirtying up more dishes than absolutely necessary! Much easier this way! Once the bowl of scooped out fat chunks cool, they will go in the trash. Sorry for the gross looking photos but this is what it looks like folks… and now we wait…

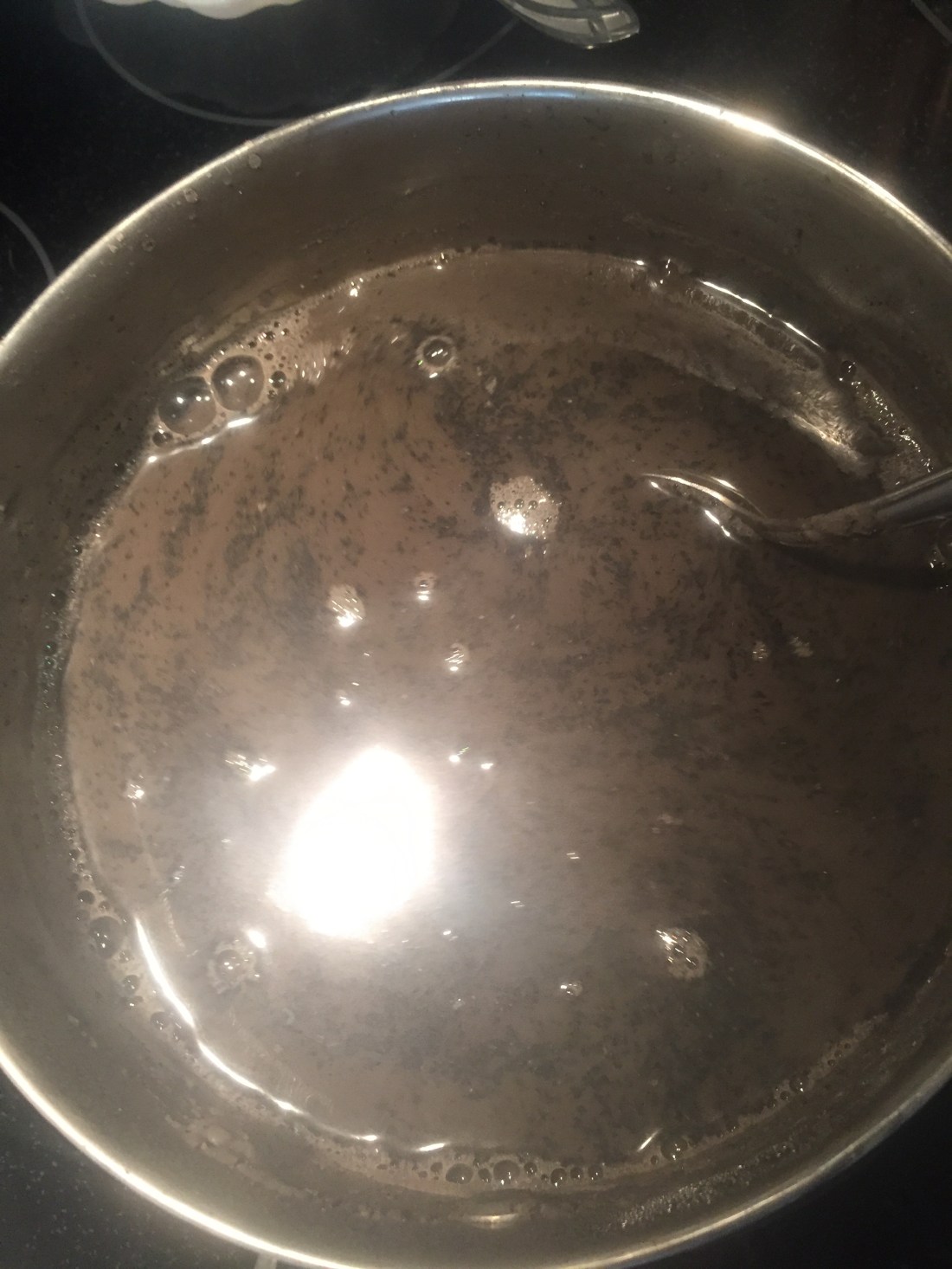

now to the actual making of the wood ash lye part which has me a bit nervous to be honest! I dumped the ashes in my stainless steal soap making pot, added enough water to give about an inch over the top of the ashes… and simmered and stirred constantly for 30 minutes. You really do have to stir the entire time!

And to my amazement the mixture went from memories of making mud pie soup (yes I was giggling at these memories) as a child in the back yard and trying to get the dog to eat it (and my sister lol)… to a shiny almost varnish shellac looking sheen on the top of the water! Amazing!!!! Well that thar must be the lye I’m supposed to skim off the top once it has cooled and the ashes have settled back down to the bottom! Eureka! And I didn’t eat a hole in the pot or the stirring spoon (my silent unspoken fear lol) so I guess I must be doing this right? I also haven’t passed out from fumes so … heck this isn’t as scary as everyone makes it sound like! I’m still gonna be cautious with it don’t get me wrong but I was imagining needing a haz mat suit or something lol. That being said… I am totally experimenting here folks so disclaimer: if you try this at home do your research, be careful and I can’t be held liable for your using this post as a how to guide because… it’s not. It’s a record of a personal living history experiment! So there!

My jar of “lye” water is now ready to go!

I harvested some peppermint from the garden. Not at its most potent because we have already had a snow here in Montana but I want to go with what is available naturally like the pioneers would have used. I decided to chop them with my herb blade… which actually does better than a blender for small amounts of herbs anyway.

My tallow (aka lard) has been chilling in the fridge since yesterday and looks all nice and pretty and ready to go!

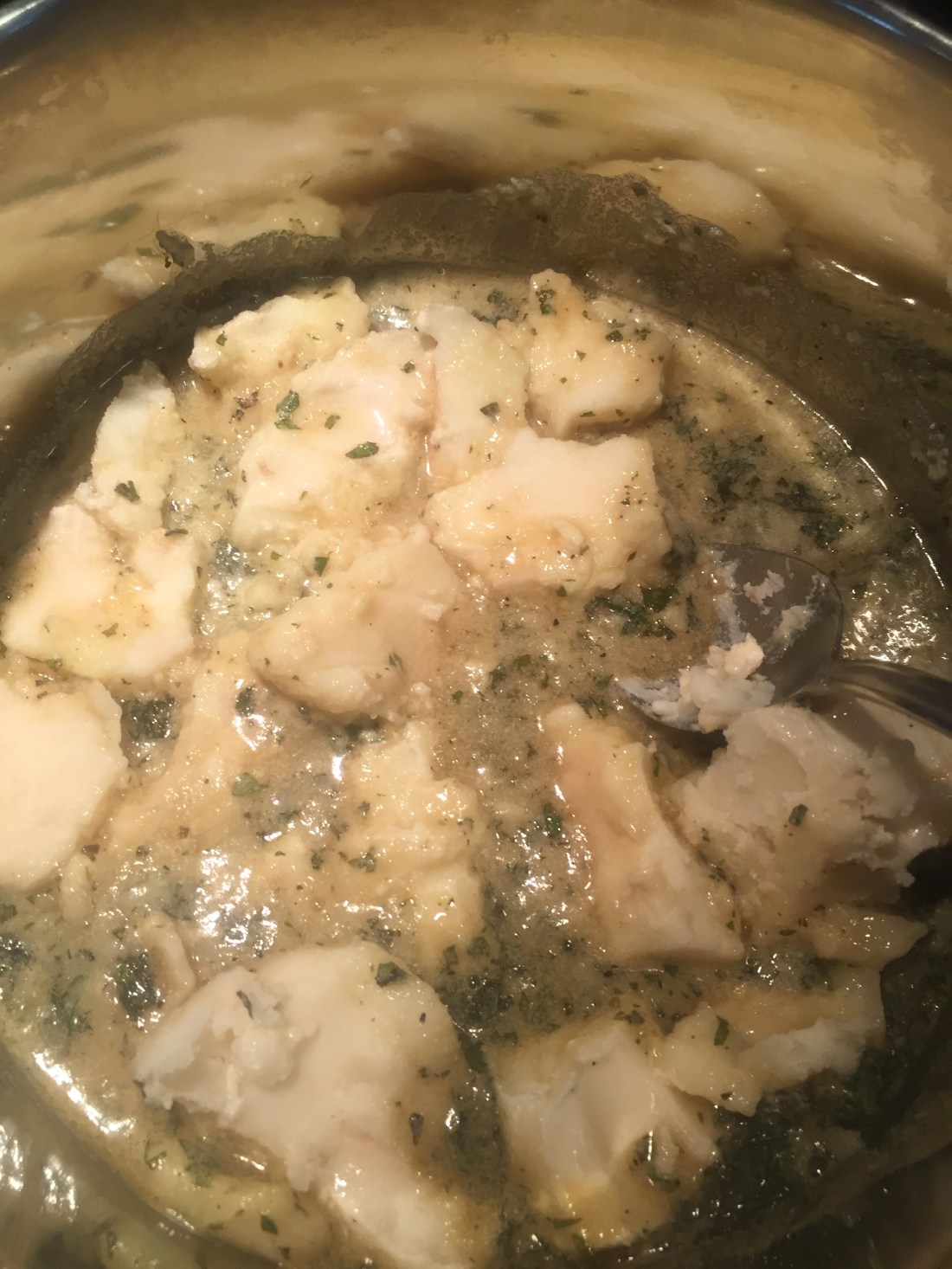

So time to melt it all together! So exciting! I THINK! I have about a pound of lard/tallow. So I’m going to use 2/3 cup of lye water and 1/4 cup of salt and a handful of finely chopped peppermint. The goal is to melt it all together to a paste like consistency. Mine came out more like a thick gravy instead of paste so I’m hoping the addition of the salt will make up for the (I think?) perhaps too much lye water? Like I said… this is an experiment folks! I poured it into a parchment lined corningware dish and now we wait …. again…. lol

It amazes me how much work went into daily living back then! I’m sure they would have made a whole year’s worth of soap in one big batch but I can’t imagine cutting that much beef, rendering that much lard, making that much lye water… and the many days of waiting in between for things to set then be melted and then wait to let it cool and set again! Not to mention the huge kettle and amount of wood needing chopped to heat the kettle! All this work for a bar of soap so you could take a bath once a week in the same bucket of (dirty) bath water your 12 siblings used before you got your turn! After you were the one that probably made the soap to begin with! And heated the water for everyone else to use first as well! Yep… humbling. A lesson in humility here folks… think about it…

Ok so back to the experiment. I bet you are totally wondering was it a success or a complete failure?!?! So excited to find out the results!!!

But guess what… you are going to have to check back in 4-6 weeks! I know, right! I totally missed the part where the soap needs to sit and “cure” for 4-6 weeks so all the water evaporates out of the mixture! Sigh… and I was so excited to see how it turned out only to find out that pioneers had to wait a long time to get a dang bar of soap! Especially if they had to wait for that calf to get big enough to butcher first lol. Modern woman just isn’t built for this amount of waiting and anticipation! Lol

I sure hope pioneer Conestoga Chuck and I can stay clean and smelling good for at least 4-6 weeks waiting on this soap to cure! I wonder what they did if they ran out of soap? I do have some soapwart plants growing in the garden if we get desperate lol maybe we should dig a few up and give those a try before the next snow! I see another pioneer living history experiment on the horizon!!!!! Yay!

What do you say Conestoga Chuck? How about a soapwart bath? Sounds like fun right? Lol

I’m gonna take that as a “no” from Conestoga Chuck lol … see how easy it is to translate doggie language?!?!